BC Robotics

Browse categories

- New Additions

- Shop

- On Sale / Clearance

- Popular Categories

- ArduinoArduino is the most popular open source microcontroller platform on the market. These easy to program devices can read sensors, control relays, light up LEDs, and even talk to one another. Their ability to interact with the real world by way of sensors and other electronics makes them ideal for automation such as watering a plant when it is dry, reading the weather, or controlling lights when it gets dark – the possibilities are endless. We carry a variety of Arduino compatible microcontrollers from several manufacturers, each with their own specific strengths and purposes. To further specialize your microcontroller, we carry a large selection of daughter boards (shields) which can add powerful sensors, GPS, or even LCD screens to your project! Just getting started with microcontrollers? We carry a variety of Arduino starter kits to get you reading sensors and blinking lights as easily as quickly as possible!

- BBC micro:bitThe BBC micro:bit is a pocket-sized computer designed for beginners in electronics and coding. The micro:bit makes getting into these often daunting fields as easy as possible. Programming the micro:bit V2 can be done by computer or by their intuitive app available for Android and iOS devices. Code can be designed using a drag and drop interface in the Blocks editor, Javascript, or Python.

- ESP8266 & ESP32The ESP8266 and ESP32 microcontrollers from Espressif are powerful, inexpensive, and feature integrated WiFi connectivity. These are ideal for IoT applications. We offer a variety of different ESP8266 and ESP32 modules for different skill levels.

- FeatherFeather is a flexible and powerful family of microcontroller main-boards (Feathers) and daughter-boards (Wings) designed with portability in mind. All Feathers have integrated battery connectors (and most have built in lipo chargers) The Feather form factor is not locked to a specific chipset or programming language. Feathers are available with a variety of chipsets and on-board features. Most Feathers and FeatherWings have example code and libraries written in Arduino C/C++ and CircuitPython.

- Makey MakeyThe Makey Makey kit is a electronics kit designed for beginners. It explores the concepts of creating circuits through everyday items. When plugged into a computer you can use the Makey Makey to make anything into a keyboard or mouse. No programming required! Projects like a Banana Drum Set, Cat Detector, Musical Stairs, and countless others are easier than you think! We carry the Makey Makey Classic Kit – a starter kit for the Makey Makey – along with extra alligator clips, copper conductive tape, and replacement cables.

- Raspberry PiThe Raspberry Pi was first introduced in early 2012 as a simple, low cost, computer fit onto a circuit board roughly the size of a credit card. The idea was to use this low cost computer to promote teaching of computer science in schools but it has grown to be so much more! Since its release, well over 30 million of these little computers have been sold. We have carried the Raspberry Pi in Canada since it first became available and have watched as the Pi has morphed into a complete development platform with powerful single-board computers, cameras, touchscreens, and other accessories. Its multitude of inputs and outputs for electronics and computer peripherals and its impressive computing power mean it can be used to make just about anything you can imagine. The newest and most powerful version, the Raspberry Pi 4, is now available!

- Popular Brands

- AdafruitAdafruit was founded in 2005 by MIT engineer, Limor “Ladyada” Fried. Her goal was to create the best place online for learning electronics and making the best designed products for makers of all ages and skill levels. In the last 10 years, Adafruit has grown to over 100+ employees in the heart of NYC with a 50,000+ sq ft. factory.

- ArduinoArduino is an ever growing platform used by some of the most popular microcontrollers out there. For many of us, this is where it all started – the Arduino was (and still is today) a pioneer when it comes to making programming hardware easy and accessible. We have one of the largest selections of Arduino and Arduino accessories in Canada. These range from basic Arduino Uno, to Cellular and WiFi connected devices perfect for the Internet of Things, and all the accessories needed to get them running!

- Micro:bitMicro:bit Educational Foundation are the manufacturers of the popular BBC micro:bit; a pocket-sized computer designed for beginners in electronics and coding. The micro:bit makes getting into these often daunting fields as easy as possible. Programming the micro:bit V2 can be done by computer or by their intuitive app available for Android and iOS devices. Code can be designed using a drag and drop interface in the Blocks editor, Javascript, or Python.

- BC RoboticsIn addition to stocking 2000+ unique items, we also manufacture our own accessories right here at BC Robotics. In 2014 we began developing our own widgets and add-ons for Arduino, Raspberry Pi, and general prototyping. This has now grown to over 80 different SKUs. Our boards are assembled in-house with top quality components. Many feature detailed tutorials or project guides to get you up and running as quickly as possible!

- Raspberry Pi

- SparkFunSince 2003, SparkFun has been helping turn ideas into reality – whether you’re creating a smart weather station, exploring the frontier of machine learning, building a robot for school or prototyping your first (or tenth) product. No matter your vision or skill level, our open source components, resources and online tutorials are designed to broaden access to innovative technology and make the road to a finished project shorter. We’re here to help you start something.

- Frequently Asked Questions

- My Account

- Wishlist

- Cart

PRODUCT TUTORIAL

- Chris @ BCR

- August 19, 2022

- 3:46 pm

- 2 Comments

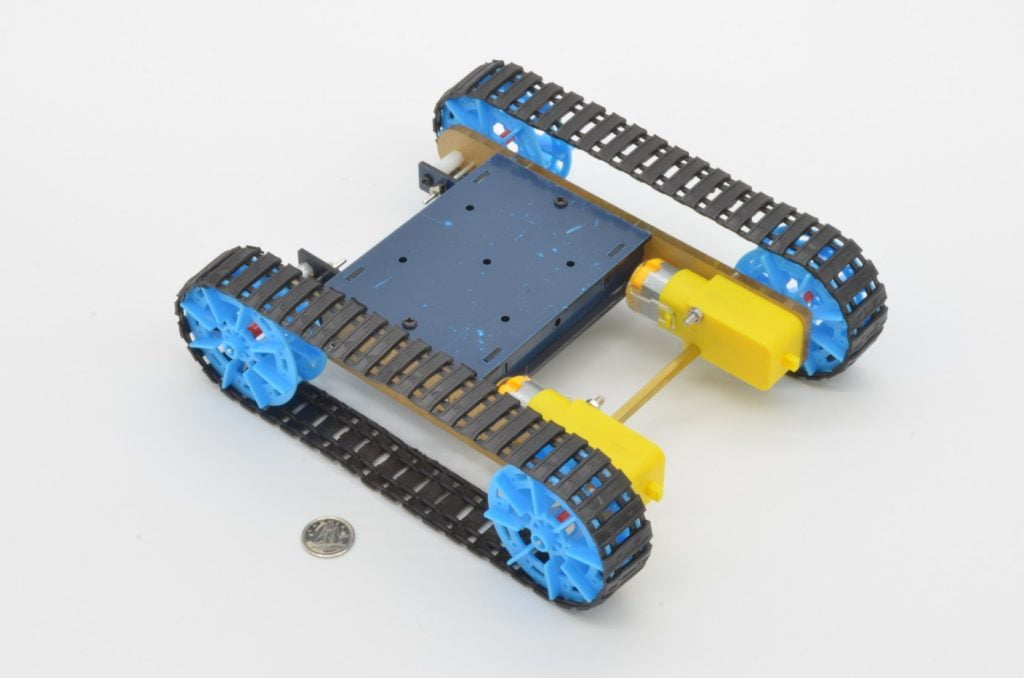

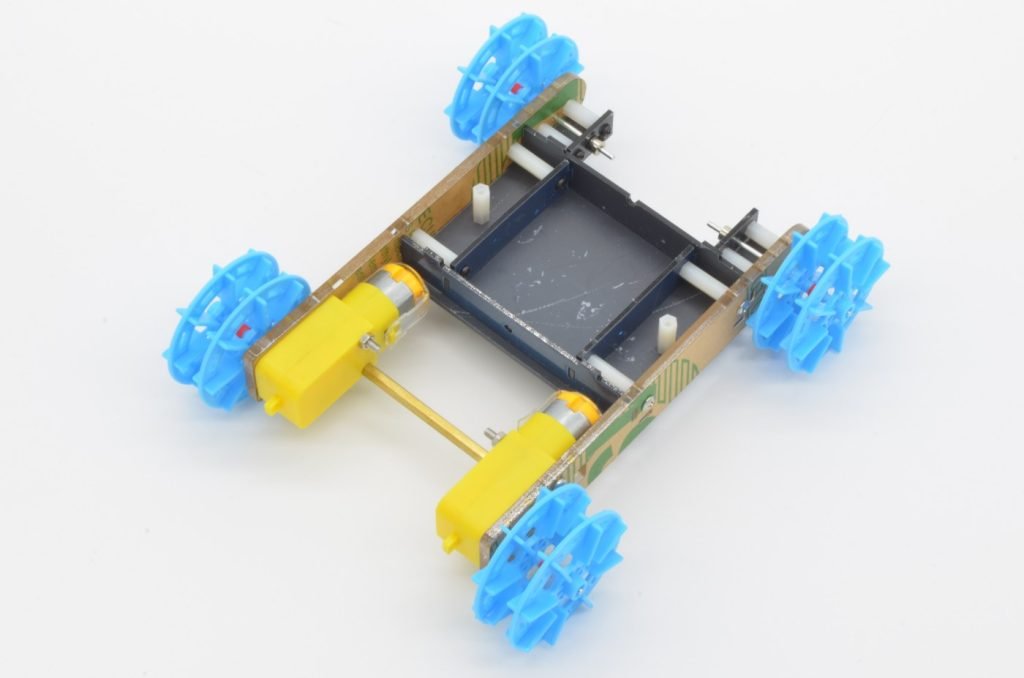

Wheeled robots are fun and all… but tank tracks are just so much better! In this tutorial we are going to assemble our Tank Track Chassis. The chassis features a variety of different sized screws and standoffs so pay careful attention to which parts are required in each step.

About The Chassis:

This chassis is very similar to most of our two wheel drive chassis, utilizing a single motor for each side. Just like those chassis, this Tank Chassis can be turned left and right by differential motor speed. This chassis should be compatible with just about any project using two “TT” style gearmotors to drive.

Recommended Tools

This kit includes a couple very basic tools to complete assembly, but nice tools always make the job more enjoyable! Screws this size are quite delicate and using the wrong sized screwdriver can cause them to strip out or wreck the finish.

Recommended:

- Assorted Small Screwdrivers – Precision Screwdriver Set

- Small Pliers – SparkFun Needle Nose Pliers

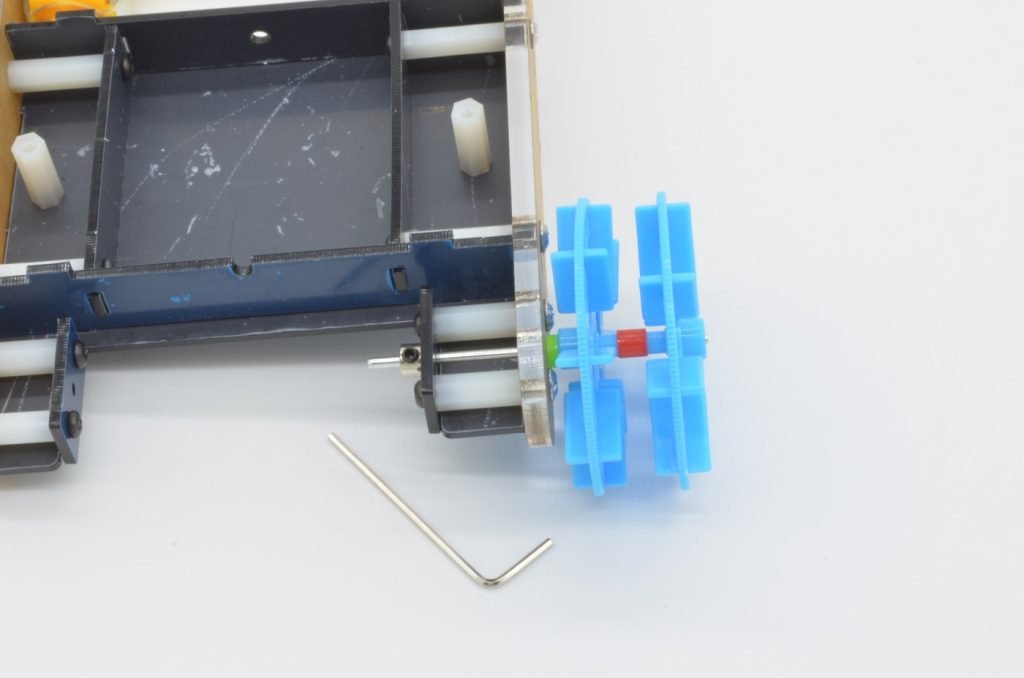

- 1.5mm Allen Key

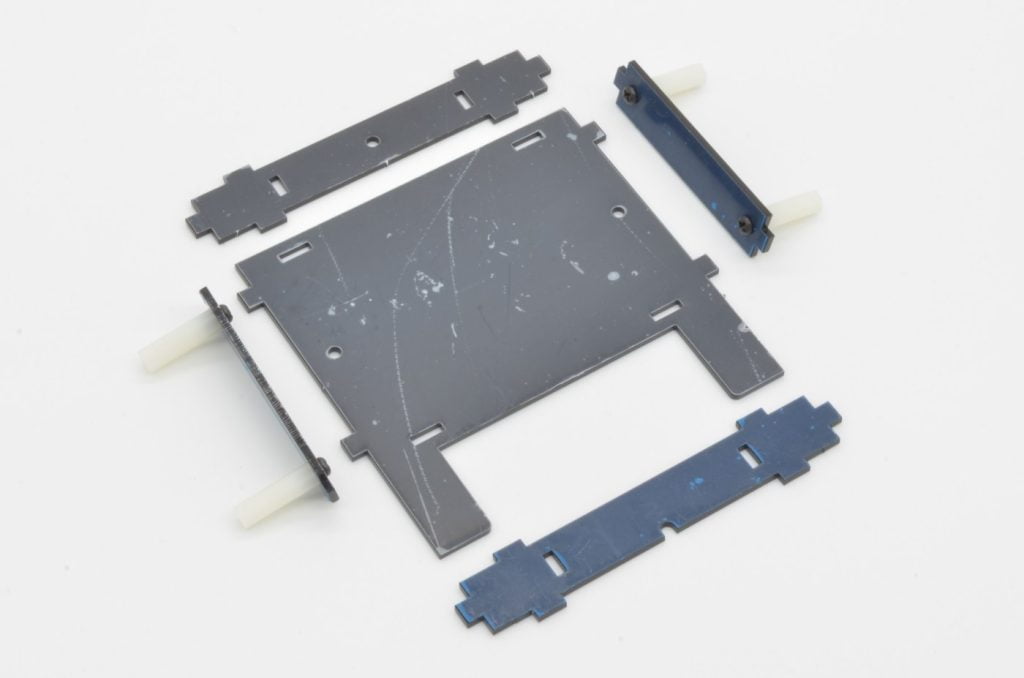

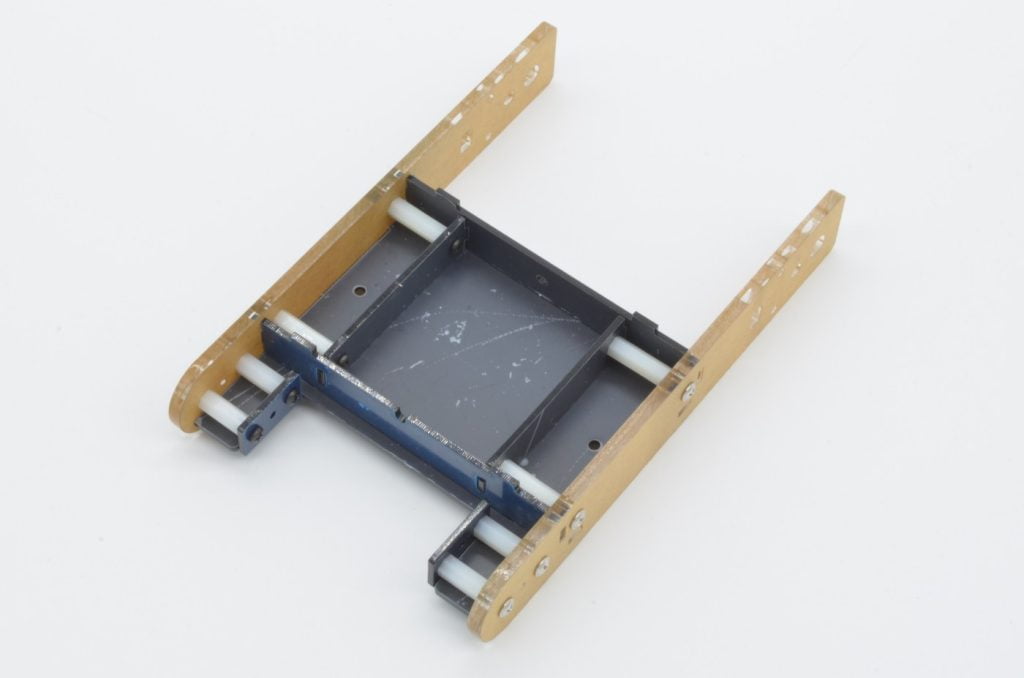

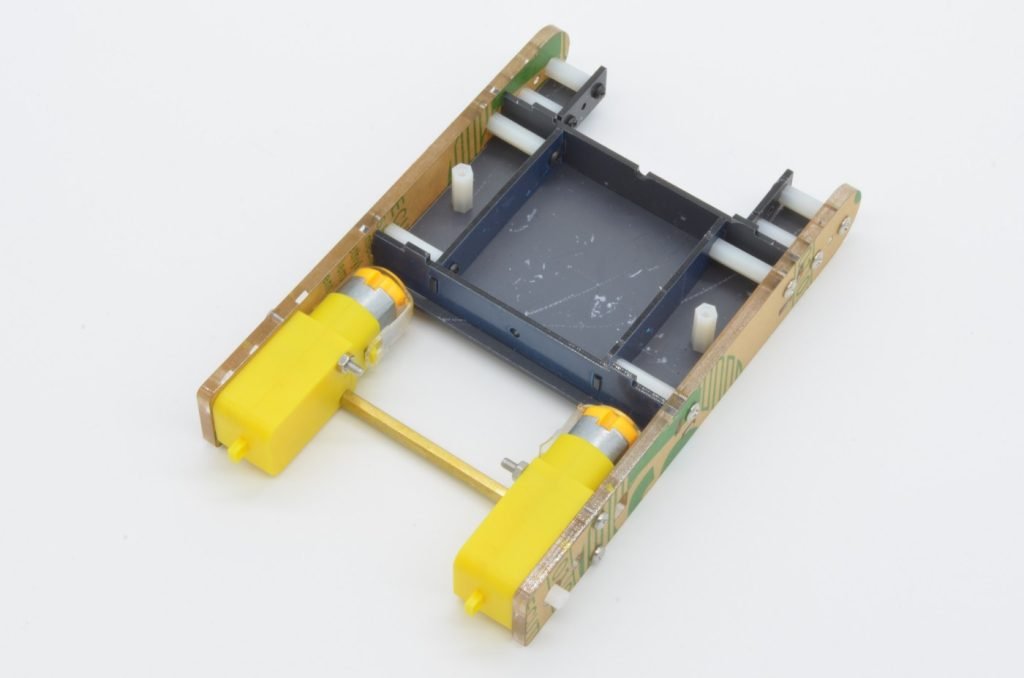

Step 1 - Inner Structure

We are going to start by assembling the inner structure of the chassis – this is the box that everything else connects to, and provides a base for further expanding the chassis or housing electronics. There are several parts that fit together in a specific manner, but we will work through it step by step!

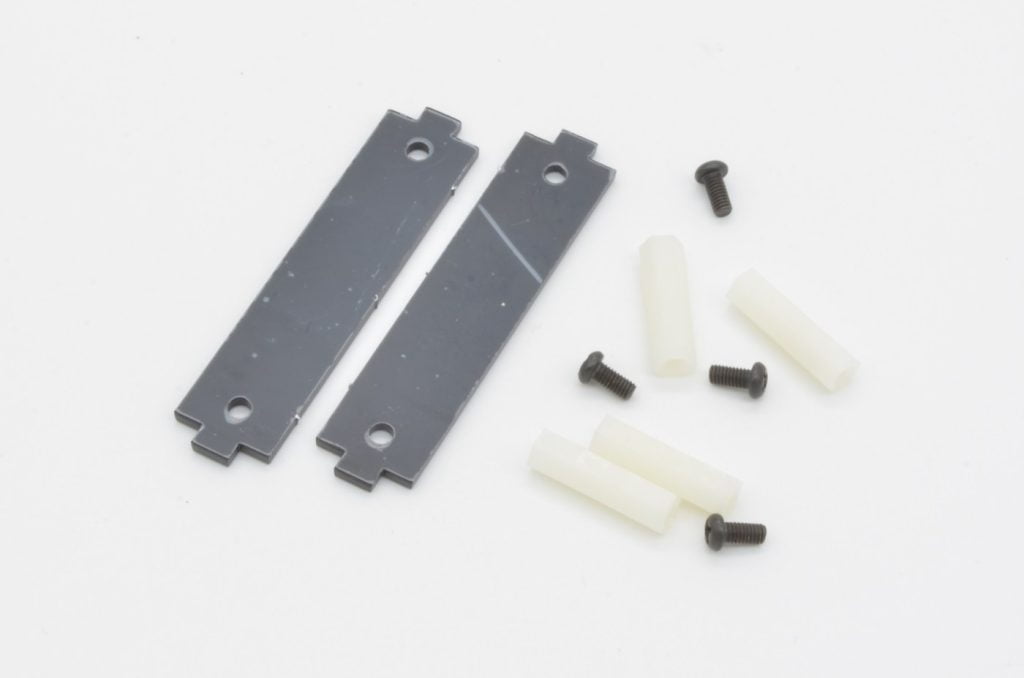

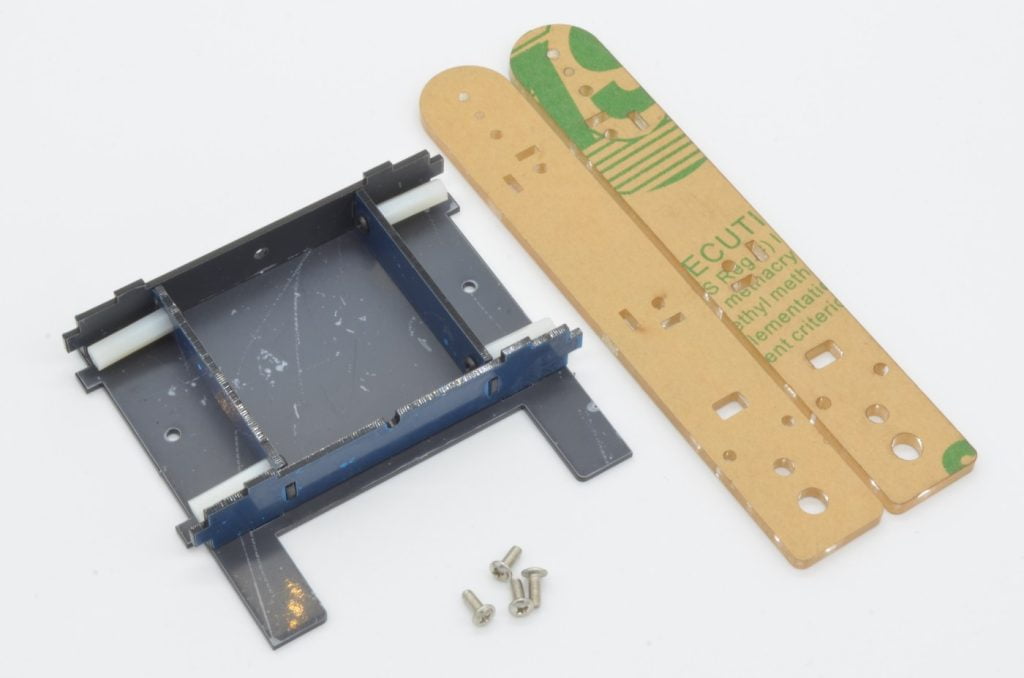

First, start by finding the two small acrylic plates (seen in the image to the left) and 4 x 20mm Standoffs, 4 x M3 Black Screws

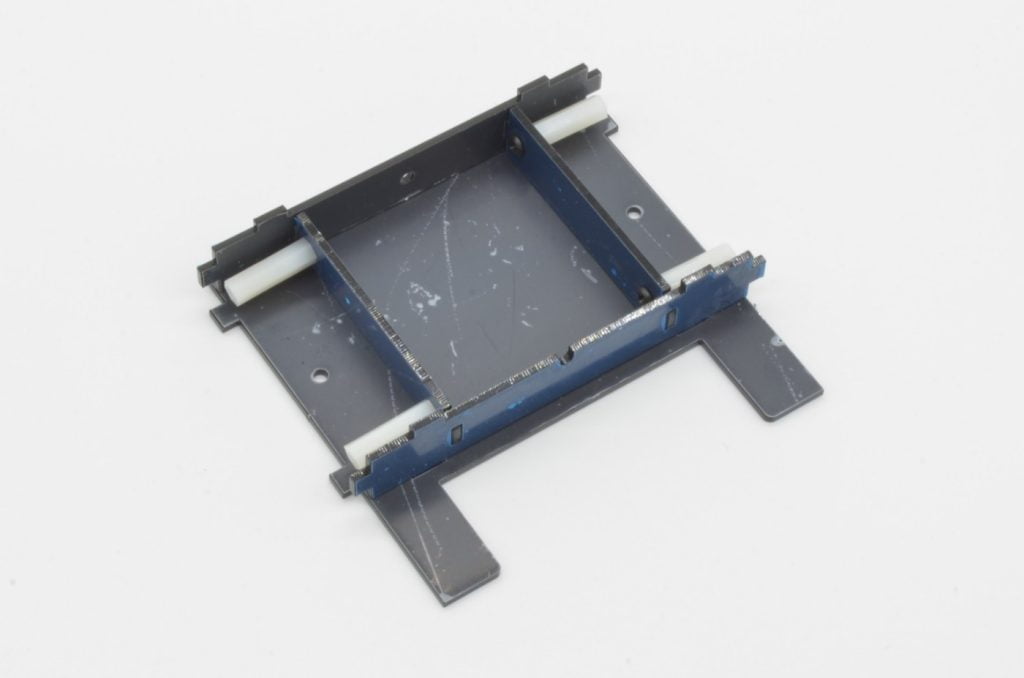

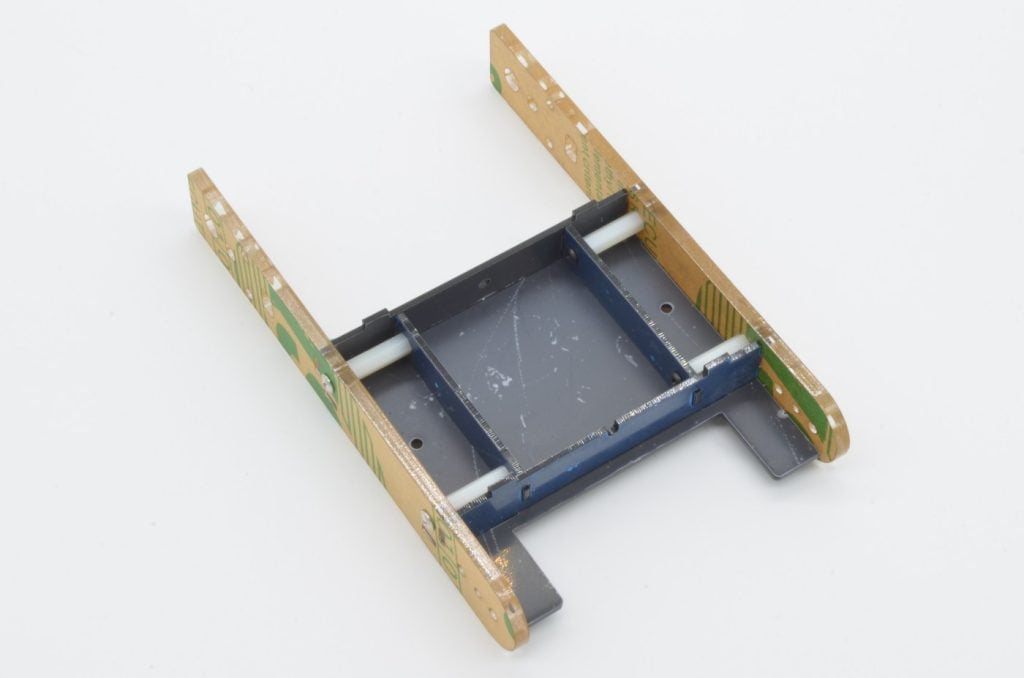

Step 2 - Inner Structure (Continued)

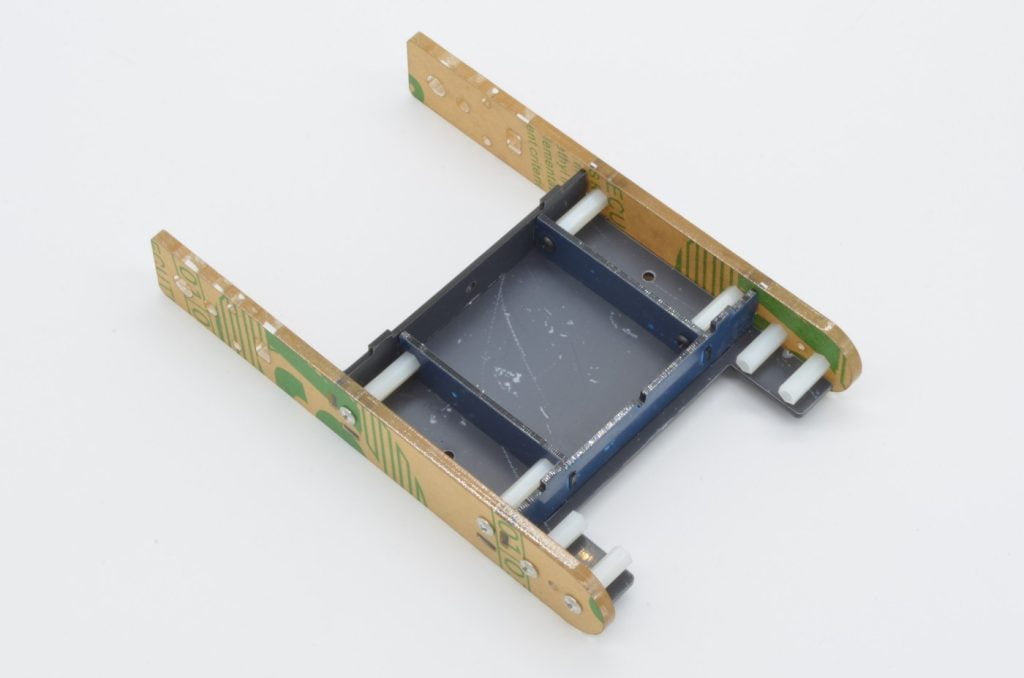

Step 3 - Outer Structure

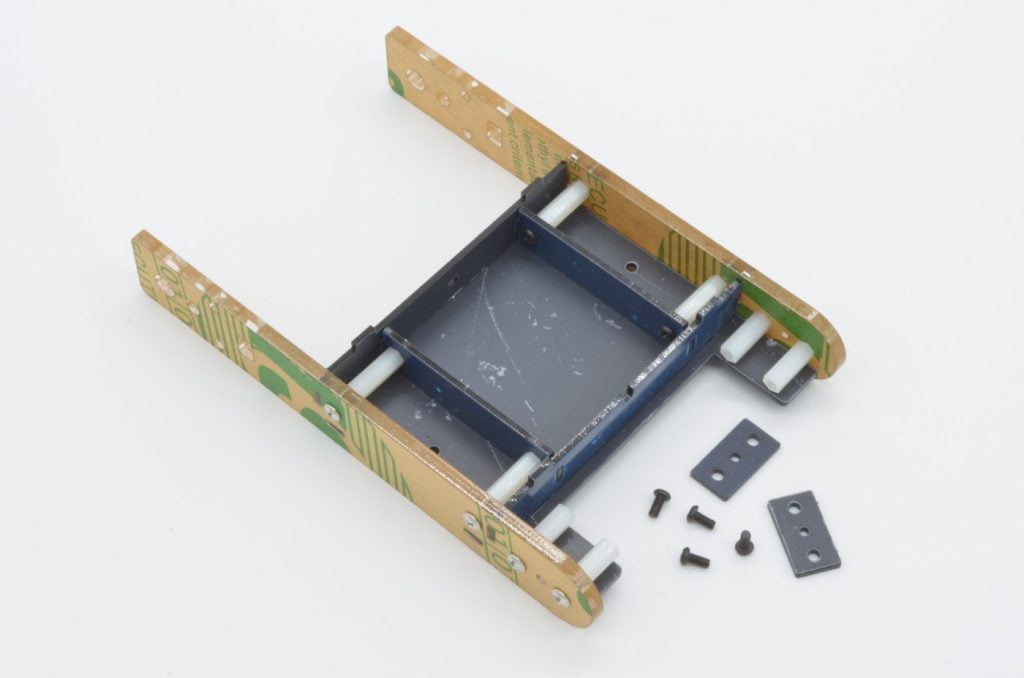

Step 4 - Idler Wheel Brackets

Step 5 - Idler Wheel Brackets (Continued)

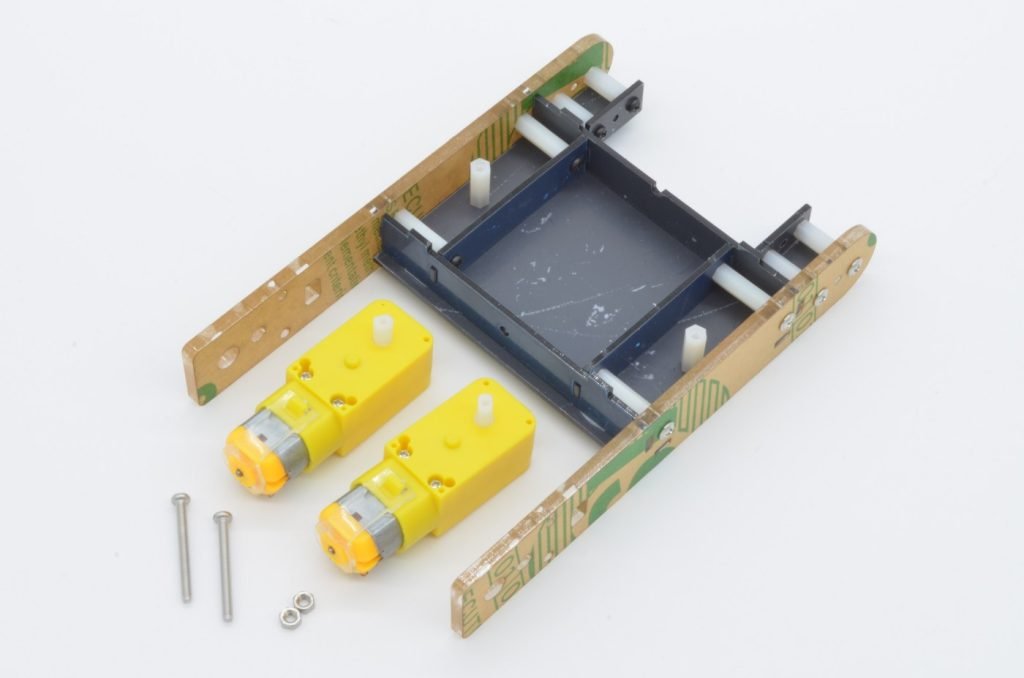

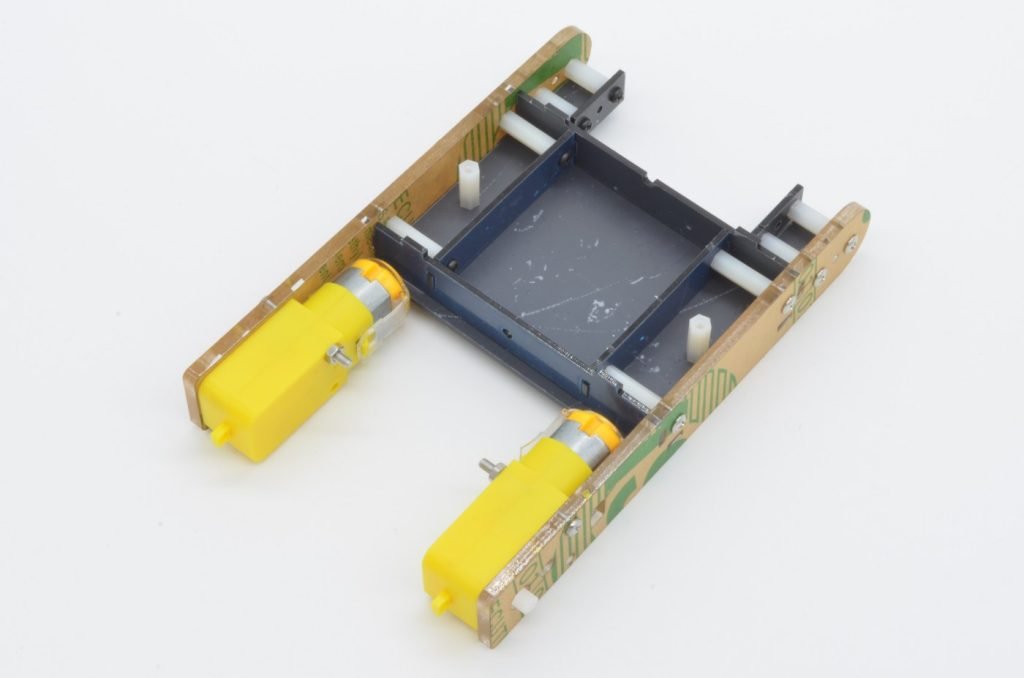

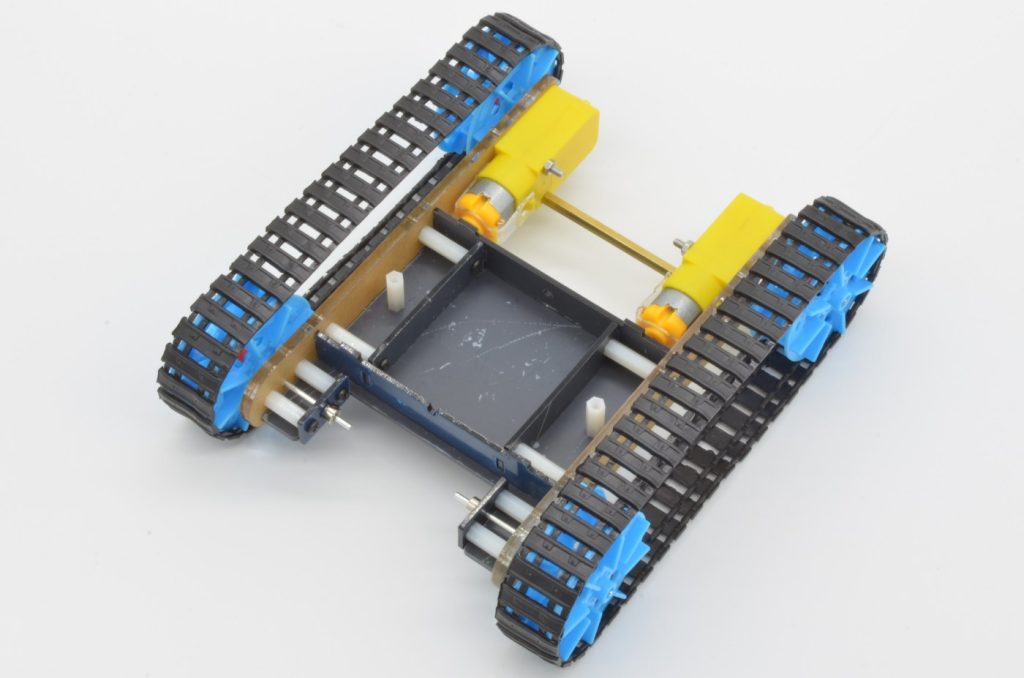

Step 6 - Adding The Motors

The motors are attached to the chassis using two screw points. We are going to start by attaching the top screw to each motor. Find 2 x 30mm screws and 2 x M3 nuts.

Note: Depending on your application, you may want to solder wires to your motors before installing them to the chassis. The tabs can be a little harder to access once installed.

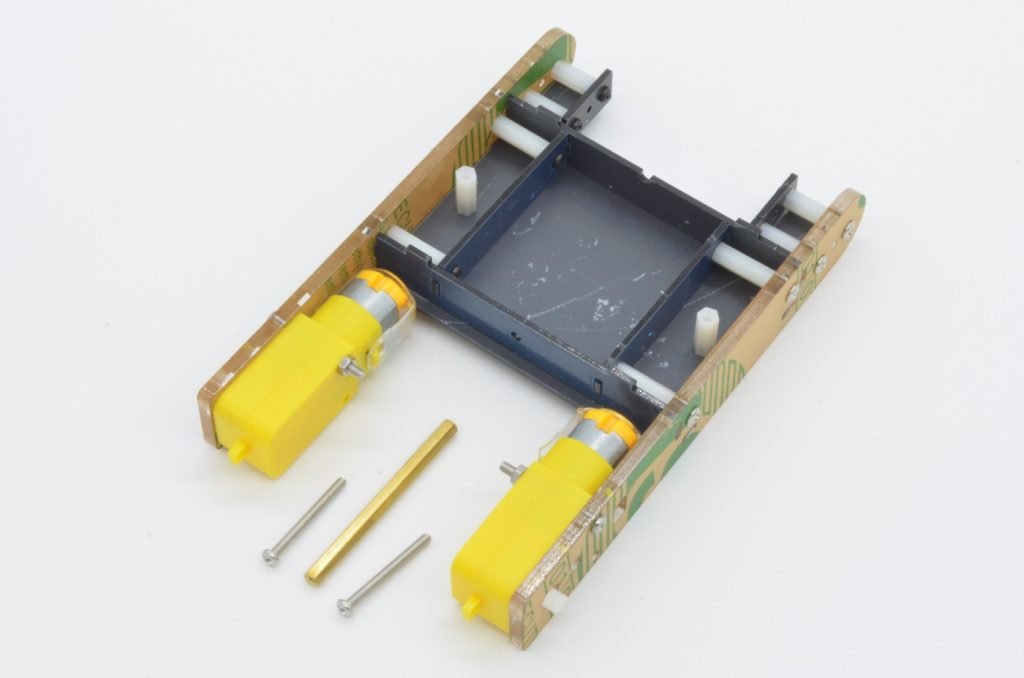

Step 7 - Lower Motor Brace

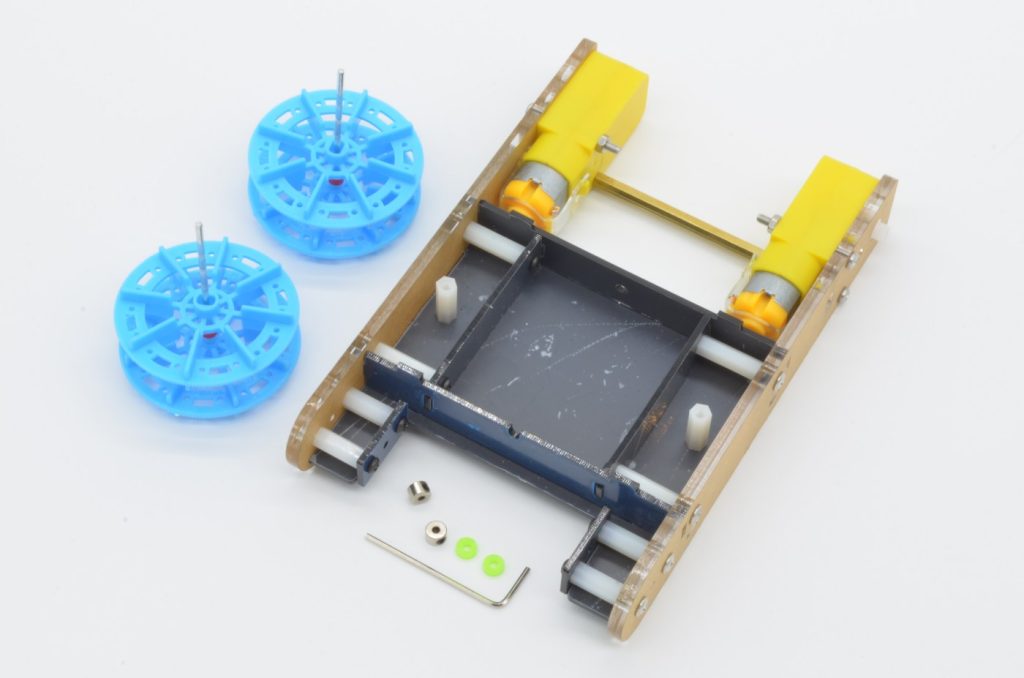

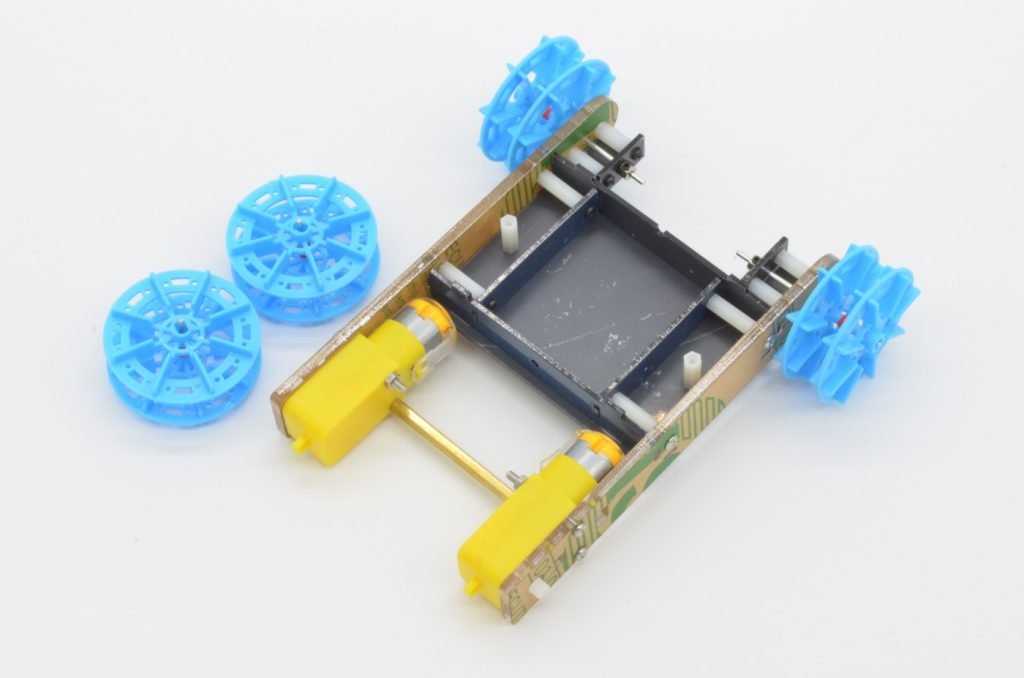

Step 8 - Idler Wheels

Step 9 - Drive Wheels & Tracks

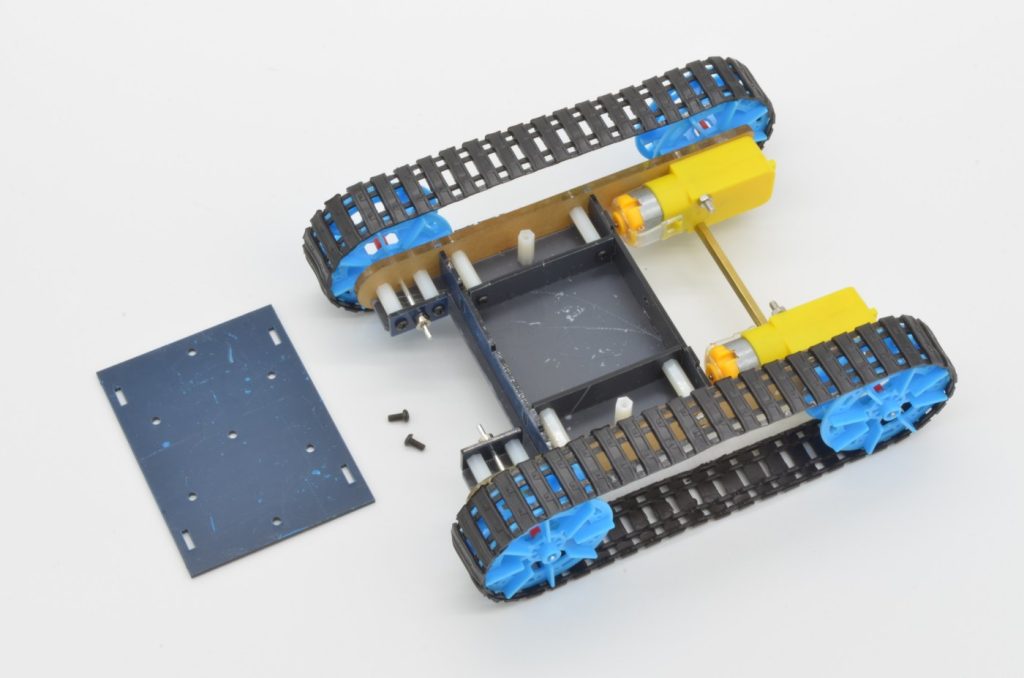

Step 10 - Cover Plate

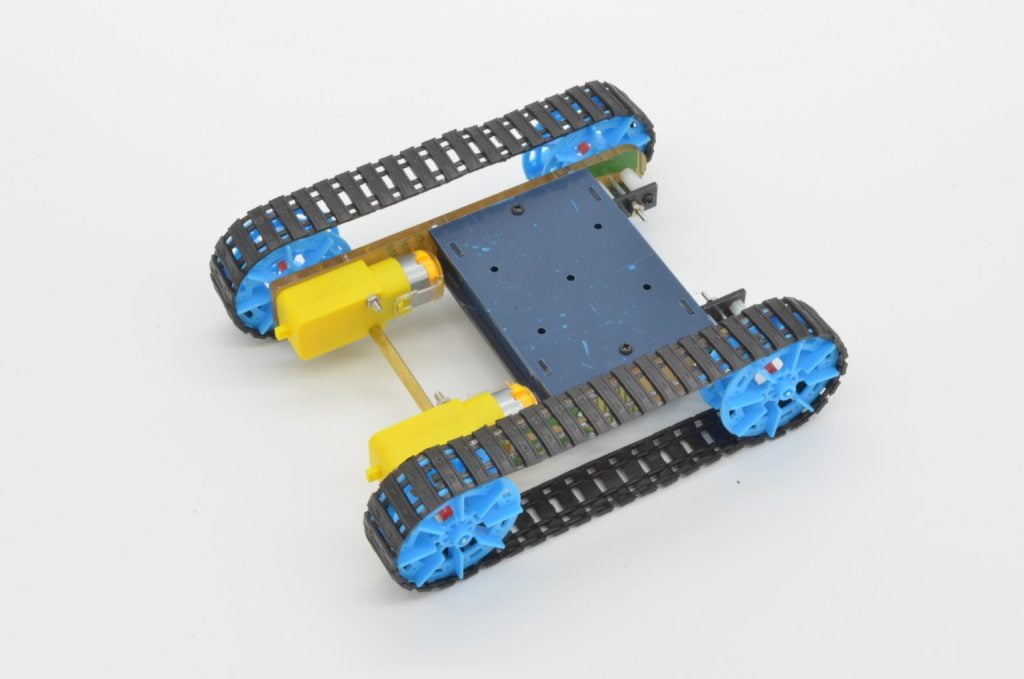

Finally we can install the last cover plate. This plate finishes the internal structure of the chassis. Inside the panel there is room for electronics or a small battery pack. There are 5 mounting holes that can also be used to anchor a larger plate or mount electronics on the outside of the chassis.

The panel is secured using 2 x Black Screws. These thread into the standoffs inside the chassis.

And with that last plate installed, the chassis is complete! Now add the motor controller and microcontroller of your choice and you are well on your way to a tracked robot!

Going forwards, many aspects of the chassis can be upgraded. The TT style motors are easily upgraded to a version compatible with wheel encoders, or even metal gears for added strength. The chassis can be expanded to provide more build space. Of course, sensors can be mounted all over to provide data about its surroundings.

2 thoughts on “Tank Track Chassis Assembly Guide”

Mark Edwards

Step 6 shows parts on the chassis to f attach the lid (step 10), but there are no instructions telling you to install them.

xsm

– All the plastic and acrylic parts are covered with protective film. If you peel everything off before starting, you get a shiny black core with transparent sides.

– Step 5 goes before 4. I assembled mine using the supplied tools and the screwdriver was too long for step 5 after step 4, so I had to undo 4, do 5, and then redo 4.